The upcoming trends of Core Drilling Equipment technology

Wiki Article

Checking Out Core Drilling Equipment: Essential Tools for Precision in Geotechnical Investigations

Core boring tools plays an essential role in geotechnical investigations. These specialized devices allow designers to extract accurate examples from diverse geological formations. Understanding the different parts, such as drill rigs and core little bits, is vital for efficient tasting. As innovation advances, so also do the techniques used in core boring. The effects of these advancements on safety and security and precision increase vital concerns about their application in real-world jobs. What obstacles remain in enhancing these tools?Summary of Core Exploration Equipment

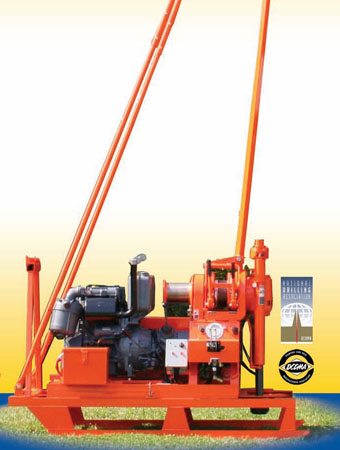

Core exploration equipment is necessary for removing round examples from different geological formations. This devices commonly consists of a drill rig, diamond or carbide-tipped drill little bits, and core barrels made to keep the tasted material. The drill rig supplies the necessary power and stability for the drilling operation, often featuring hydraulic systems that make it possible for efficient infiltration into acid rock or soil. Drill bits are crafted to hold up against extreme pressure and abrasion, making certain effective puncturing various products. Core barrels play a crucial role in capturing and preserving the integrity of the samples, enabling accurate geological evaluation. The equipment is frequently mounted on lorries or trailers for movement, making it possible for access to remote places. In addition, developments in innovation have actually brought about the development of computerized and mobile core drilling systems, enhancing functional performance and safety. Overall, core drilling devices is crucial for rock hounds and engineers in their mission to recognize subsurface conditions.Sorts Of Core Exploration Rigs

Core drilling rigs been available in numerous types, each designed for geological conditions and certain applications. Rotary boring gears, ruby core drills, and wireline core systems stand for the key groups utilized in the sector. Recognizing the attributes and advantages of each gear kind is crucial for efficient core sampling and geological expedition.

Rotating Boring Rigs

When exploring the numerous sorts of core drilling rigs, rotary boring rigs attract attention as a result of their effectiveness and adaptability in drawing out geological samples. These rigs utilize a revolving drill bit that reduces via rock and dirt, making them excellent for a large array of applications, consisting of mineral exploration and ecological evaluations. Rotating drilling gears can be categorized into various types, such as truck-mounted, trailer-mounted, and portable systems, each developed for functional demands and certain terrains. The gears usually utilize a boring liquid to cool the bit and lug drill cuttings to the surface, improving the overall drilling procedure. Their durable design and versatility make rotary boring gears a preferred option in geotechnical examinations, facilitating specific and trustworthy example collection.Diamond Core Drills

Ruby core drills stand for a specialized category of exploration tools developed for high-precision geological sampling. These drills make use of diamond-impregnated bits, allowing them to reduce via tough rock formations with outstanding performance. The key benefit of diamond core drilling exists in its capability to create continuous core examples, which are essential for geological evaluation and mineral exploration. Readily available in numerous sizes and configurations, ruby core drills can be adapted for different midsts and geological problems. They are usually mounted on portable gears, making them flexible for area applications. The precision of diamond core drilling not just boosts the quality of accumulated examples yet also minimizes the danger of contamination, therefore making certain trustworthy data for geotechnical investigations.Wireline Core Solutions

Wireline core systems represent an ingenious innovation in core drilling innovation, permitting for effective retrieval of core examples from considerable depths. These systems make use of a wireline technique that makes it possible for the continual removal of core examples without the need to repeatedly pull the entire drill string from the borehole. This ability significantly lowers downtime and boosts operational effectiveness. Wireline core systems are especially useful in challenging geological problems, as they lessen disturbance to the borehole and preserve example integrity. Various sorts of wireline core rigs exist, customized for certain geological environments and project requirements. Their flexibility and effectiveness make wireline core systems a favored choice in modern-day geotechnical investigations, guaranteeing specific information collection for design and environmental evaluations.Crucial Core Little Bits and Their Applications

Core little bits offer as essential devices in the area of boring, allowing the removal of cylindrical samples from numerous geological formations. These bits are designed to permeate various materials, including rock, dirt, and concrete, each with specific applications tailored to the geological context. Ruby core little bits are preferred for their sturdiness and effectiveness when reducing with tough rock, making them ideal for mineral expedition and geotechnical analyses. Alternatively, carbide-tipped core bits are generally used for softer developments, offering a cost-effective service for acquiring samples in less tough atmospheres. Additionally, specialized core little bits, such as those equipped for environmental boring, assurance minimal disturbance to the surrounding location, which is very important in contamination assessment projects. The option of core little bit straight affects the quality of the examples accumulated, therefore influencing subsequent analyses and decision-making in design and ecological assessments.Improvements in Core Drilling Technology

Recent innovations in core exploration modern technology have actually substantially boosted the performance and performance of geological sampling. Advanced exploration gears currently integrate automation and remote monitoring capabilities, enabling drivers to gather data in real-time while decreasing human intervention - Core Drilling Equipment. These developments lead to improved precision and faster completion of drilling jobsAdditionally, the development of high-performance ruby core bits has changed the infiltration capabilities of exploration equipment, allowing deeper and more difficult geological developments to be sampled effortlessly. New products and layers utilized in bit manufacturing enhance durability and lower wear, significantly extending the lifespan of core drilling devices.

The combination of computer-aided design (CAD) software enables for specific preparation and execution of exploration operations, making it easier to adjust to differing geological problems. Generally, these technological advancements not just enhance the core exploration procedure yet likewise supply geotechnical specialists with very useful data for informed decision-making.

Safety Considerations in Core Drilling Operations

Safety factors to consider in core drilling procedures are critical to making certain the health of employees and the honesty of the job. Correct training for drivers is vital, as it equips them with the required abilities to deal with equipment safely and identify potential hazards. Personal safety devices (PPE) such as helmets, gloves, and eye protection need to be put on to minimize threats related to flying debris and hefty machinery.Furthermore, regular safety and security audits and danger evaluations need to be conducted to recognize and attend to any prospective dangers on-site. Ensuring that devices is effectively protected and kept can prevent crashes associated with devices failure. When boring in restricted areas to stop direct exposure to unsafe gases, sufficient ventilation is additionally important. Furthermore, developing clear interaction protocols amongst employee advertises a safer working environment. Inevitably, promoting a society of security is essential for the successful implementation of core drilling operations.

Servicing and maintaining Core Boring Equipment

Keeping and servicing core drilling equipment is important for guaranteeing peak performance and extending the life expectancy of the equipment. Routine examinations must be performed to identify damage on important elements such as drill bits, motors, and hydraulic systems - Core Drilling Equipment. Proper cleansing after each usage assists eliminate debris and protects against rust, which can considerably impact performance. Lubrication of relocating parts is necessary to minimize rubbing and avoid getting too hot, while also enhancing functional efficiencyScheduled upkeep routines, including changing used parts and inspecting fluid levels, should be purely abided by. Operators needs to additionally be educated to identify signs of malfunction, enabling timely repair work and lowering downtime. Keeping substantial service records help in tracking the tools's performance background and predicting future upkeep needs. Overall, proactive upkeep not just maintains the honesty of core exploration devices yet also adds to more secure and extra exact geotechnical investigations.

Instance Studies: Effective Applications of Core Boring in Geotechnical Projects

Core boring has shown important in numerous geotechnical jobs, specifically in framework growth and environmental analysis researches. Study illustrate exactly how this method assists in the collection of important subsurface data, informing click this task preparation and implementation. These successful applications highlight the my explanation convenience and effectiveness of core boring in resolving complex geotechnical obstacles.Facilities Growth Projects

Just how do successful facilities advancement jobs utilize core boring to enhance geotechnical evaluations? Core drilling acts as an essential device in examining subsurface conditions, enabling engineers to get trusted soil and rock examples. Such assessments are considerable for establishing the viability of sites for different frameworks, including bridges, highways, and passages. Significant case research studies show just how core drilling has been used in large-scale projects, such as the construction of city transit systems. In these circumstances, core examples supplied crucial data on soil composition and groundwater levels, promoting educated decision-making pertaining to foundation design and product choice. The assimilation of core boring into framework advancement not just improves task timelines but also minimizes threats linked with unexpected subsurface difficulties.Environmental Assessment Studies

While evaluating ecological impacts is vital for sustainable development, the application of core drilling in geotechnical jobs has actually proven to be vital. Core boring makes it possible for the collection of subsurface examples, providing crucial data on soil composition, groundwater degrees, and pollutant presence. Different study highlight its effectiveness in evaluating potential environmental dangers before construction starts. In a coastal growth task, core examples recognized high levels of salinity in the dirt, triggering alterations to the original layout to reduce future erosion dangers. Likewise, in metropolitan locations, core exploration has actually contributed in recognizing buried contaminants, guaranteeing that removal efforts are effectively aligned with task objectives. These applications highlight core exploration's role in cultivating notified decision-making and promoting environmental stewardship.Often Asked Inquiries

How Do I Choose the Right Core Drilling Tools for My Project?

To choose the best core boring tools, one ought to think about project specifications, soil types, depth requirements, and spending plan restraints. Consulting with specialists and evaluating equipment efficiency scores can additionally provide valuable insights for educated decision-making.What Are the Prices Related To Core Drilling Tools Rental?

Expenses connected with core exploration devices rental generally differ based on devices kind, duration, and area. Generally, prices vary from $100 to $1,000 each day, with extra fees for shipment, upkeep, and needed accessories.Can Core Exploration Devices Be Utilized in Numerous Soil Kinds?

Core boring devices can be properly used across numerous dirt types, including sand, rock, and clay. Its versatility enables for precise sampling and analysis, making it a beneficial tool in varied geotechnical atmospheres and applications.What Is the Typical Life Expectancy of Core Boring Tools?

The average lifespan of core drilling tools normally varies from 10 to twenty years, depending on elements such as upkeep techniques, usage regularity, and the problems in which the devices is operated during exploration projects.Just How Do Environmental Problems Affect Core Drilling Operations?

Environmental problems considerably impact core boring operations. Variables such as soil moisture, temperature variations, and weather patterns can affect devices performance, drilling speed, and the quality of examples acquired, inevitably influencing job end results and timelines.Rotary boring gears, diamond core drills, and wireline core systems represent the main classifications made use of in the industry. When exploring the different kinds of core drilling rigs, rotating boring gears stand out due to their effectiveness and versatility in drawing out geological examples. The key advantage of diamond core drilling lies in its capacity to produce continual core samples, which are necessary for geological evaluation and mineral exploration. Wireline core systems stand for an innovative development in core boring modern technology, permitting for effective retrieval of core samples from considerable depths. Costs connected with core exploration tools rental normally differ based this hyperlink on equipment place, period, and type.

Report this wiki page